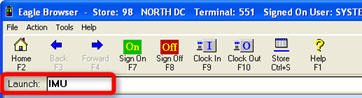

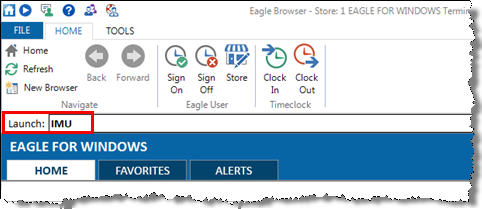

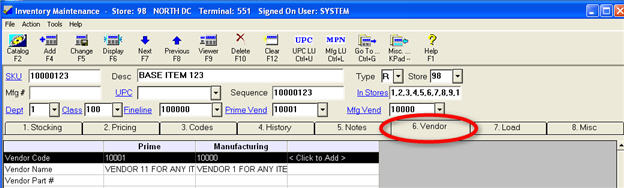

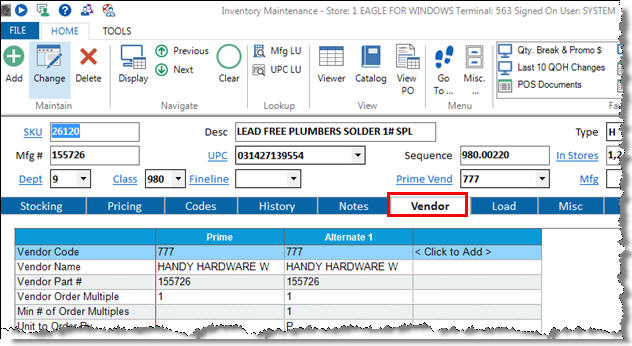

When setting up item records in Inventory Maintenance (IMU) to use with Buyer’s Purchasing, you must fill in certain fields on the Vendor tab and the Misc tab. These tabs hold data that tells the system if the item is stocked in the distribution center (DC) or not, and what are the vendor order multiples if ordered direct or split through the DC.

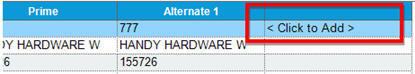

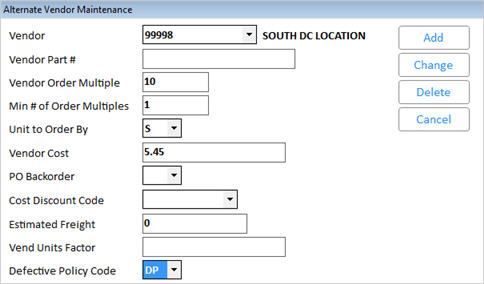

Because PO Worksheet (POW) uses alternate vendor records as it creates purchase orders, any vendor from which you want to order must have an alternate vendor. If you have DC locations, you must have an alternate vendor for each DC. For example, if you order an item from a primary vendor and that item is also distributed by the warehouse, you need two alternate vendors, one for the primary vendor, and one that represents the DC vendor code. Note: Alternate vendors can be added and updated using the Inventory Import Tool.

-

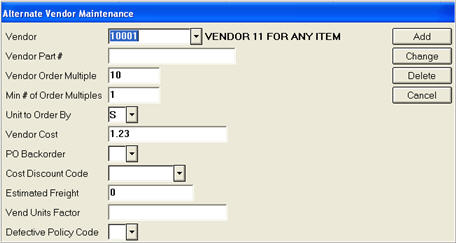

VendorThis field is required. Select the appropriate vendor from which you order this item.

-

Vendor Part #This field is required if this is not the DC Vendor. Enter the vendor part number for this item.

-

Vendor Order MultipleThis field is required. If this vendor is the same as the Primary vendor, this field must match the Order Multiple. If this vendor is the same as the Mfg Vend, this field must match the Standard Pack. If this is a distribution center (DC) vendor, enter how you will pull the product from the DC for the retail stores. For example, if the DC breaks the vendor case and sells the item by inner pack of 4, set this field to 4.

-

Min # of Order MultiplesThis field is required and should always be set to 1.

-

Units to Order ByThis field is required. It defaults to S for stocking units, but if the vendor requires ordering in purchasing units, change this field to P.

-

Vendor CostIf this vendor is the same as the Primary vendor, or if the vendor code is one of your distribution center (DC) locations, set this to the Replacement cost. Product is sent to the stores via transfer; this cost is used to allow the buyer to view the estimated total for the transfers. Note: If you have an alternate vendor that matches the Primary vendor, changing the replacement cost on the Pricing tab automatically changes the same vendor’s cost on the Alternate Vendor tab.

-

PO BackorderThis field is not required. If left blank, it will follow the vendor’s default setting.

-

Cost Discount CodeThis field is not required. You may want to leave this field blank to allow the item to follow the default in the vendor record, unless this item has a different discount than the vendor normally allows. Note: If you enter a value, it displays an asterisk as a visual indicator that this item is not following the vendor's default Cost Discount Code.

-

Estimated FreightThis field is not required, and you should probably leave it blank to allow the item to follow the vendor's default setting. If this field is populated, the purchase order reflects a set dollar amount for this item’s freight charge. This value is only used for the purchase order; it does not define how freight is landed during receiving. Note: If you enter a value in this field, it displays with an asterisk next to it as a visual indicator that this item is not following the vendor default.

-

Vendor Units FactorThis field is not required and defines how many stocking units make up one vendor unit. The vendor record defines a minimum for how many are required. For example, canned dog food product comes 12 cans to a case, but the vendor has a requirement that you order at least 2 pallets of product (any item). You would enter the number of cases that make up one pallet of this item. This does not mean that you order this item by the pallet, but the number you have ordered will total some partial pallet amount, and will be included in the total pallets calculated in PO Worksheet.

-

Defective Policy CodeThis field is not required. If you enter a value, it displays with an asterisk as a visual indicator that this item is not following the vendor default setting.

If you have several items to process, the most expedient method for updating these is the Inventory Import Tool, as it can update alternate vendors immediately.

-

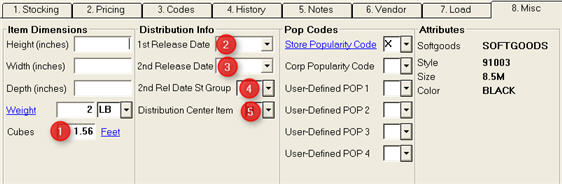

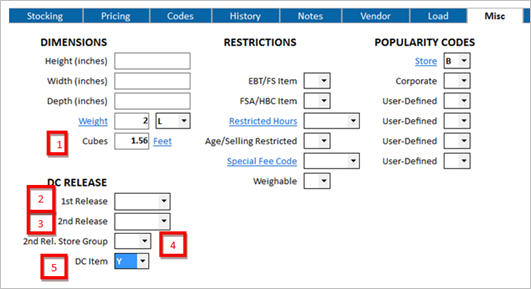

CubesThis field is not required, but if you use freight factors that are based upon cubes, you must populate these fields first (also available in Inventory Import, if you have this feature). The value is in cubic feet, but for international shipping, you can view and enter them in cubic meters by clicking the Feet/Meters hyperlink.

-

1st Release DateThis field is not required. If product is brought into a DC in advance of a season and you want to hold the merchandise until a specific date, populate this field. Most often this field is updated from a purchase order. Product that would normally go out on replenishment orders is held until this date, at which time it is distributed based upon demand.

-

2nd Release DateThis field is not required. If product is kept in a DC that is seasonal in nature, you may want to ensure that all stock of this item is out of the DC while it is still in season. For example, if you want to distribute the remaining stock of Christmas lights in the DC to the stores on December 18, whether or not their sales indicate they need them, populate this field with 12/18/10. When this date is reached, all stock is forced to the stores.

-

2nd Release Date St GroupThis field is not required. The store record for the DC contains a default store group to be used when the second release date is reached, but you may want to limit which stores are forced to get product by entering a store group in this field.

-

Distribution Center ItemIf this item might ever have a quantity in the DC, set this field to “Y” so that the system will allow you to order stock to be received at the DC. If this field is set to “N”, you can bring merchandise in through the DC, but only as splits or pass-thru orders.